Rotor 1×13 – Hydraulic drivetrain with 390 % gear range

The Rotor 1×13 is the world’s first hydraulic drivetrain with a 13-speed cassette. Thanks to its modular design it promises to be an excellent option for all roadies, crossers and gravel riders. We’ve taken a closer look to give you all the details.

Why is 2×11 equal to 14?

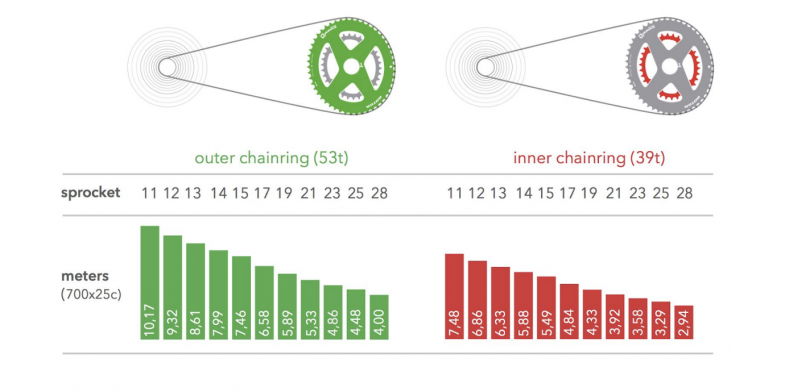

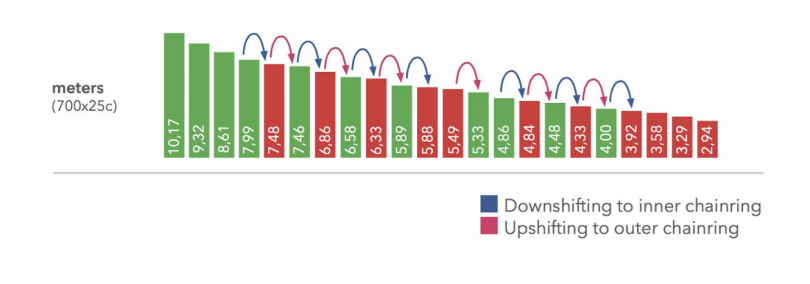

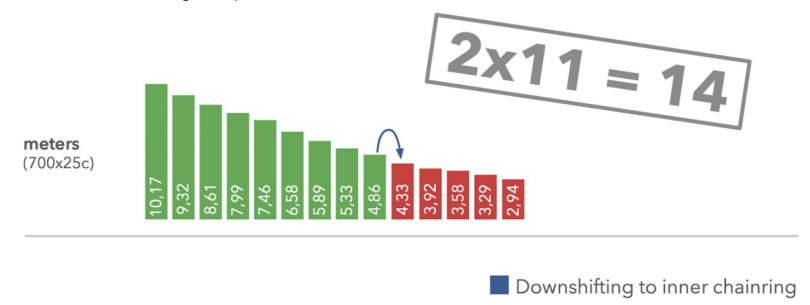

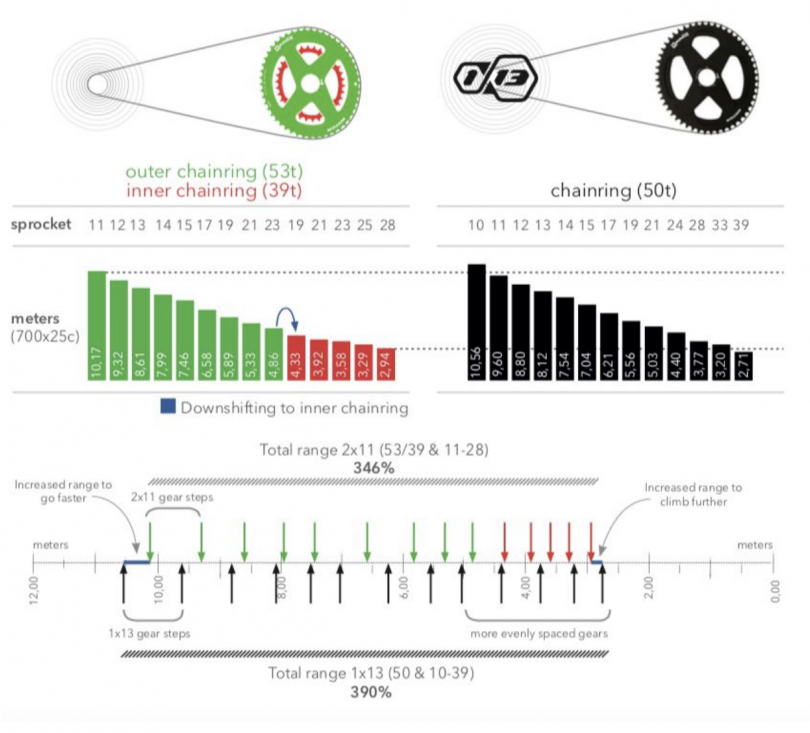

As Team Aqua Blue Sport has shown, 1x drivetrains have already made their way into road racing. The system is not undisputed, however, due to the large gear steps. Conventional 2×11-drivetrains (53/39 and 11-28T) theoretically have 22 gears, but according to Rotor, only 14 different gears get used.

Following this graph, the rider would have to change the chainring 13 times to shift through all gears in an orderly fashion. According to the company’s experience, riders usually shift the derailleur until a gear change with the front mech becomes necessary. So if you assume that you only shift once with the front derailleur while shifting up or down through the full gear range, you use a total of 14 gears.

Why 1×13?

Rotor believes it is only a question of time until 1x drivetrains will start to catch on in the road bike segment, and they want to offer finer gradation with the 1×13 compared to 1×11 alternatives. The company sees aerodynamic advantages in a 1x drivetrain in particular. Also, the use of the system for racing is an exciting prospect, since the absence of the front mech means there is no risk of having to shift gears at the decisive moment, which significantly reduces the risk of chain jamming. People who use 1x drivetrains will be quick to tell you that shifting is a lot more intuitive and the system boasts a lighter weight.

Why hydraulic shifting?

According to Rotor, the main advantage of a hydraulic derailleur is that the system is maintenance-free. No battery to charge, no cables to replace. In addition, the weight of the complete system promises to be less than that of electronic or mechanical alternatives. Rotor also claims that shifting remains precise without needing adjustment.

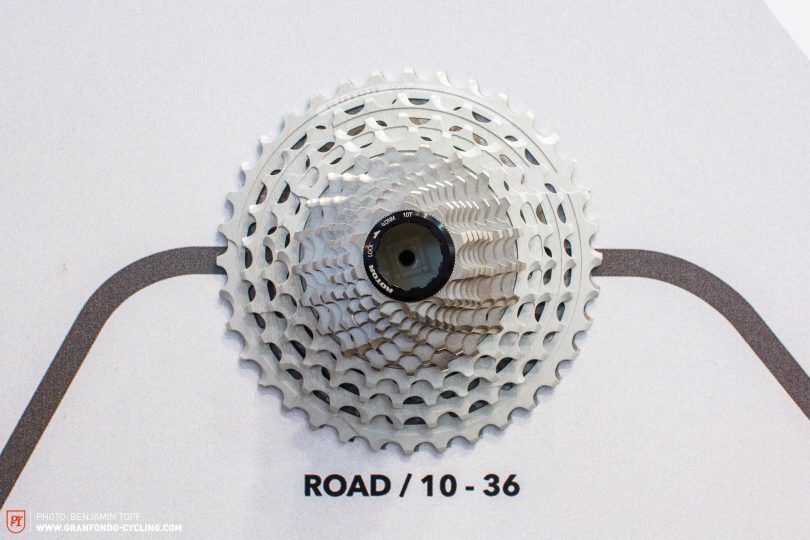

Rotor uses the existing components of the UNO groupset for the shifters. Fully hydraulic, both shifting and braking. To adapt the 1×13 groupset to your riding preferences, Rotor offers four cassettes in sizes 10-36, 10-39, 10-46 and 10-52 in addition to differently dimensioned chainrings. The only drawback: commercially available hubs are not compatible with the 13-speed cassette, so at present only the Rotor hub with a 12×142 mm Thru-Axle will work.

Our opinion of the Rotor 1×13-drivetrain

With the 1×13 drivetrain, Rotor presents a system with a total gear range comparable to that of 2×11 alternatives. We can imagine it’ll work really well for gravel riding. It remains to be seen to what extent the system will achieve acceptance on the road. As soon as we get to do an in-depth review of the groupset, you’ll be the first to read about it here.

More information is available at rotorbike.com

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of GRAN FONDO, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: