German company MAHLE are one of the largest suppliers in the automotive industry. Despite partners such as Specialized, SCOTT and ORBEA, however, they’re still rather unknown in the bike industry. But that’s set to change. What are MAHLE doing to achieve this, and will their automotive expertise suffice? We visited them in Palencia to find out.

From the automotive industry to big players in the ebike business. Sound familiar? That’s right, MAHLE are striving to mimic Bosch’s success story. While MAHLE are well known in their hometown of Stuttgart, Germany, where they employ a lot of people, they’re often overshadowed by the three automotive giants Mercedes, Porsche, and Bosch, and the latter have already enjoyed great success in the ebike sector. MAHLE, on the other hand, are still rather unknown, despite large investments and equally large success in this segment. With the X35 and X20, the German company already have two hub motor options in their portfolio with a lot of potential. You can find them on numerous electric road bikes from well-known brands and they’ve even been awarded the Design & Innovation Award. Furthermore, MAHLE have proven what they’re capable of in terms of mid-mounted motors in their cooperation with the premium brand Specialized, and they plan to make the concept available to all manufacturers soon. During an exciting and insightful behind the scenes visit, we found out why the German company moved to the north of Spain to do so, how they’re tinkering with new motors, and what else they’re planning.

MAHLE – ¿Hablas español?

Why is the ebike division of a traditional German company based in Palencia, Spain? MAHLE employ over 70,000 people, operating internationally. Formerly, the company Ebikemotion were located in Spain, until they were acquired by MAHLE at the end of 2018, taking over the location along with its employees. Western Spain offers the ideal conditions for extensive ebike motor testing. Located in the Castilian highlands, the office is in the immediate vicinity of mountains and trails, and the winding roads are quiet: perfect for road bike testing. The mild climate also guarantees excellent test conditions almost all year round. The employees all have access to rental bikes, for both commuting and testing. In addition to their – predominantly bicycle enthusiastic employees – MAHLE also have dedicated test riders with different skill levels. All the data collected by the test fleet get recorded and carefully evaluated, and they regularly disassemble the motors, checking them for wear. The real-world tests deliver important findings, enriching the results of numerous laboratory tests. In order to benefit from the expertise of German employees on site, MAHLE rely on expats such as test director Manuel Pal. The head of SmartBike Systems, Jochen Sommer, is originally from Stuttgart, too, now maintaining the company’s German corporate culture in its Spanish headquarters.

MAHLE – Technical success, but lacking in publicity

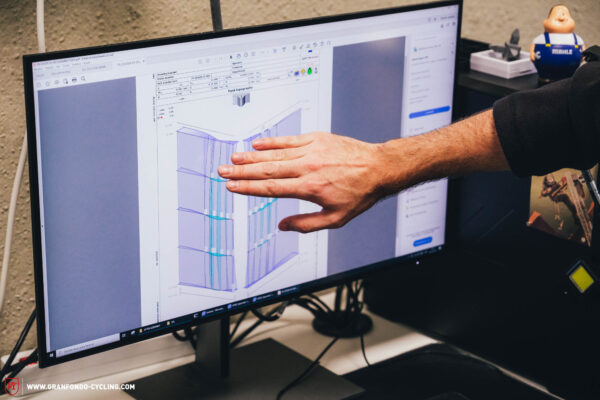

MAHLE are known as automotive parts suppliers for internal combustion engines, though they’re increasingly branching out into the e-mobility sector. While the company have been holding back in the ebike segment, they’re on track to cranking up the dials. After all, MAHLE are partly responsible for the first light eMTBs with a mid-mounted motor: first the Specialized Levo SL and then the Kenevo SL, two extremely light and capable ebikes relying on the 35 Nm Specialized SL1.1 motor (an unbranded MAHLE motor weighing just 1.95 kg) and a 320 Wh battery. The two pioneering bikes have won several awards, including the prestigious Design & Innovation Award (click here for the Specialized Kenevo SL award). Nevertheless, MAHLE didn’t get much attention when these bikes were launched. There are rumours that Specialized and MAHLE want to continue or even expand their cooperation, but it’s unclear at this point how much of that is true. MAHLE enjoyed some success in the hub motor segment with the X20, as featured in sporty e-road bikes like the SCOTT Addict eRIDE and the BMC Roadmachine AMP One. But here, too, their success was rather inconspicuous, despite the respective bike brands’ clear commitment to MAHLE motors. The compact X20 motor is hidden behind the cassette and therefore hardly visible from the side. A mini LED display on the top tube lights up in different colours, and there is hardly any visible branding, except on the button. This understatement doesn’t match the product’s performance and we’re given to thinking that MAHLE could be more successful in the ebike market with more aggressive marketing and new products. Doing so would compliment the intensive product development and quality we encountered during our visit.

The 3 pillars to success – Digitalisation, digitalisation, digitalisation

MAHLE aren’t just to be reckoned with in terms of hardware, but also when it comes to software, especially in the field of big data. The MAHLE My SmartBike app allows them to analyse real market and usage data and thus contributes massively to the optimisation of their products. Don’t worry, there’s no need to fear an Orwellian dystopia – no one will know if you sneak out at night to train some more, hit the trails, or just visit your lover. Instead, they collect meaningful and anonymised data such as the distance, support mode, travelling time, and elevation gain. They also look for interfaces within the data, like at which gradient riders adjust the support mode, for example. Voluntary data such as rider age, weight and size make the data sets even more valuable for the developers. This allows them to estimate the fitness of the average ebike user, adapting and refining the motors’ performance and support levels accordingly. The ultimate goal of these large data sets is to create the best motor for the largest possible target group. Manufacturers and users who don’t fall into the standard profile can make adjustments via the app and thus customise the motor and the bike to suit their preferences. By doing so, MAHLE also bridge the gap between customers and manufacturers, giving them access to the data and thereby allowing them to adapt their bikes to the target rider type.

Growth and what the future holds for MAHLE

It’s clear which direction MAHLE are going: up. The MAHLE SmartBike Systems used to consist of 20 people, today it’s 106, and the extension next to the complex in Palencia makes it clear that there are more to come. However, it’s not just about recruiting more staff, but also about growing their digital expertise and the ecosystem around it. They want the system to understand who is riding and adapt to their needs and preferences, ideally in real time. In the meantime, the collected data allows OEMs to adapt and optimise their bikes. MAHLE also have a clear understanding of lightweight ebike motors. The motor’s weight is constant, but the weight of the battery varies depending on capacity, and it accounts for most of the weight. A large data set can help determine the optimal battery size and thus the optimal system weight. Optionally, manufacturers could offer a range of interchangeable battery sizes, creating a modular platform that can be adapted perfectly to each customer. This leads us to MAHLE’s new take on the range extender. It doesn’t just serve to increase the capacity of the main battery and thus the range but also functions as a large power bank to charge a laptop, boombox, or smartphone from your bike – an ebike-to-device charger, so to speak. This is ideal in times of remote work and flexible hours. MAHLE also used to be rather weak in terms of marketing, seeing as they focused on B2B customers. However, MAHLE SmartBike Systems were given their own marketing department about 6 months ago, striving to increase awareness and drive effective campaigns.

MAHLE Ride Out – On the road with the X20 hub motor

Of course, the good folks at MAHLE took us out for a gravel ride. We could choose between a 3T Exploro and an open-mould frame, which MAHLE had produced for in-house purposes – each equipped with the latest X20 rear hub motor, of course. Together with R&D boss Jaume and his colleagues from product development, we could test the motor extensively on completely different setups and can say: There’s a lot of potential in hub motors yet! All the developers are enthusiastic cyclists with a deep understanding of their work and the impact it has on the motor and the bike’s handling. There’s no doubt, MAHLE have a bright electric future ahead of them.

Clearly, MAHLE have a plan: They want to use large data sets to adapt their motors and systems to the needs of real users. Doing so adds a lot of value for both the end customers, and manufacturers. However, if MAHLE want to spread the message and be seen, they must get out of their niche, build awareness, grow their reputation, and establish their values. While it won’t happen overnight, the German brand’s Spanish subsidiary are on the right path to getting there.

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of GRAN FONDO, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words: Julian Schwede Photos: Mike Hunger, Julian Schwede