For more than a century Continental’s chimney has been an imposing central figure in Korbach, Germany with machines below it whirring virtually non-stop to churn out premium bike tyres for the global market and there’s little sign that they’re slowing down. From development to production and logistics, Continental have cemented their century-old HQ in this large complex with the eye-catching chimney, opting for homemade high quality rather than outsourcing to the Far East.

I stop in my tracks. Have I somehow travelled in a time machine? Just moments earlier I’d been stood in a meeting room that screamed contemporary vibes. Using the touch screen display on the ultra modern coffee machine I’d agonised over the choice between a frozen cappuccino, a latte macchiato and a hot chocolate before sticking to my usual: a regular black coffee. I’m then led by Sebastian, head of product management at Conti, through an inconspicuous white, steel door. We leave the tranquil, white corporate space behind, the doors slams closed, and we’re greeted by steaming heat presses, rattling trolleys and all manner of bike tyres. In just a few paces, we’ve entered a whole other world of mechanised industry.

Handmade in Korbach

Conti’s HQ in Korbach is one hell of a space! Every single thing that enters and leaves through the secure gates is controlled by wardens in little huts, who clock around 3,500 members of staff coming to work each day and countless tubes and tyres for bikes, cars, motorbikes and industry that leave the grounds. There’s a lot happening, so they’ve got to keep an eye on their familiar premises. Back in 1929, Conti merged with a rubber company that was already active in Korbach, and took over the production facilities. Since then, the halls have been buzzing with inexhaustible heating machines, which admittedly look a little tired due to their rust, but are kept stringently maintained and replaced when necessary.

From the idea to the finished tyre …

… virtually every step of the tyre’s production cycle is carried out in Korbach. And despite the decision of many of its competitors to outsource production abroad, Conti made the conscious step to retain production in-house. Consequently, they’re able to cite independence, the ability to carry out full quality control and the reliance on the know-how of their own staff as just a handful of the benefits. What’s more, given the physical immediacy between development and production, they’re able to whisk up prototypes rapidly and try out new approaches. Create a stronger carcass or casing? Try out a softer rubber compound? Not a problem.

High-tech meets nostalgia

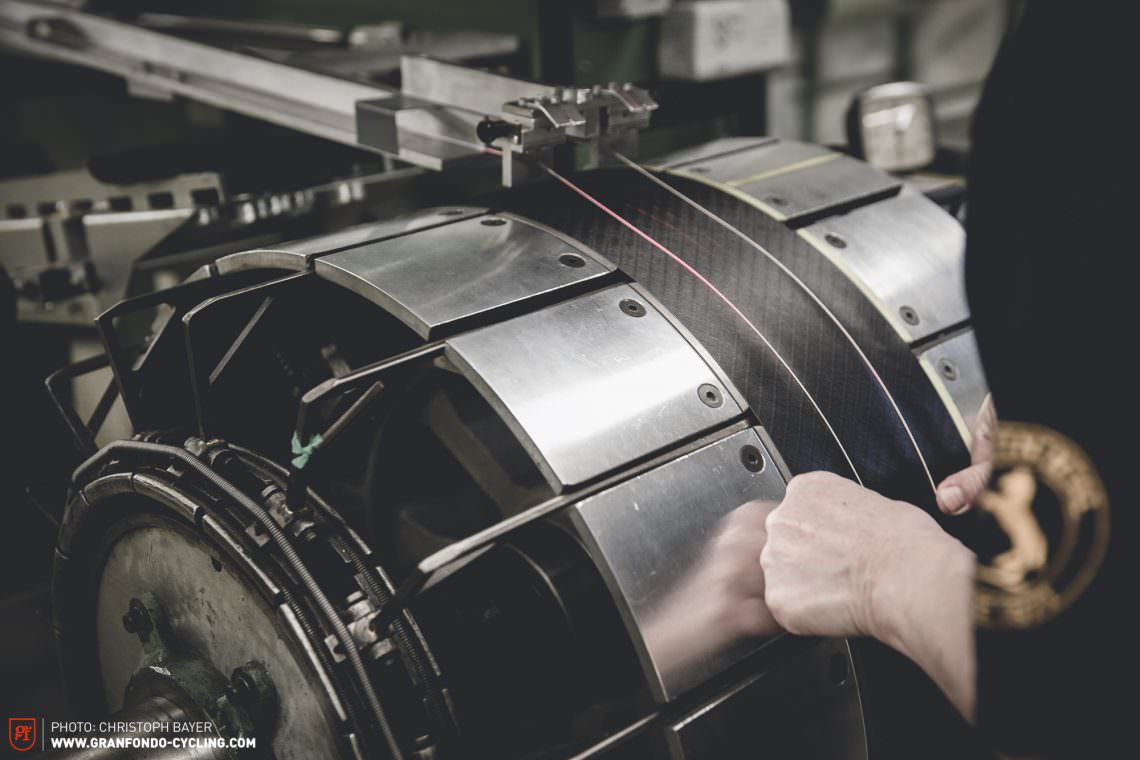

Just metres away from the slick modern office spaces, where high-tech computer programmes construct and develop tyres, staff members are still physically manufacturing the tyres using nostalgia-inducing machines. Interestingly, while the fundamentals of actual tyre production haven’t really changed over the decades, the progress of these black rings has been massive – especially in the past few years. New rubber compounds and new casings provide more mileage, less rolling resistance and better puncture protection than ever before.

If I show you then I’ll have to kill you!

… are product manager Sebastian’s words as our tour takes us in the direction of the so-called ‘Mixing Room’, where the rubber compounds are created. So while the secret formula behind Conti’s BlackChili compound still remains a mystery to us all, we were able to garner a proper insight into the rest of the process. The rubbers for the carcass, sidewall, puncture protection and tread layer are all created from different compounds, mixed and extruded out in thick slabs before further processing. Then these component parts are combined under immense heat to create a black role. These are then laid up on a roll and specific beads are added. Tyre blanks are essentially created, or at least that’s how they look to layman, purely distinguishable by the German labels on them. I’m at the inception of the Competition, a tubular racing tyre, just as it’s receiving a special layer of Vectran puncture protection. The tyre’s distinctive features are added later in one of the big heat presses. Prepared just a few metres away, the tyre blanks are then vulcanised in a giant heat press with enormous pressure for several minutes in a negative mould, much like your mum’s waffle iron. The air is the hall is hot and humid, basically t-shirt weather for 12 months of the year, although the air conditioning on the low ceiling is running to capacity throughout summer. Every time a press opens, there’s a rush of steam as the heat of the vulcanisation process is released, during which the raw material is converted into elastic rubber. And yes, it’s true: the same recognisable men and women from Conti’s ads do actually work here.

More models, more choice, more costs

A quick glance into the warehouse that stores all of Continental’s tyre moulds is enough to confirm just how vast their portfolio is. New models, new wheel sizes and, of course, the new tyre widths are all demanding a brand new design and form; consequently, more focus has been turned towards organising and planning their new offerings.

Before heading out on the trails, Sebastian and I head into the testing lab, where the tyres are scrutinised for rolling resistance, puncture risk and rips. Then we head to Willingen, 30 km from the HQ, a place synonymous in the Sauerland for bachelor parties and bowling clubs. We’re not here for that kind of party though. Instead, we’re headed for the roads snaking through the surrounding mountains to test ride the Competition Tubular, which I saw come to life only a few kilometres away. Sebastian’s riding a new prototype today, hoping to draw some conclusions about its ride quality.

But what’s it a prototype for? Well, I’m afraid if I told you, I’d have to kill you. The only thing I can confirm is that even this tyre is made in Korbach too.

For more information head to continental-reifen.de

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of GRAN FONDO, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.

Words & Photos: